SINCE 2001

ADVANTAGE

01

02

03

04

About LYD

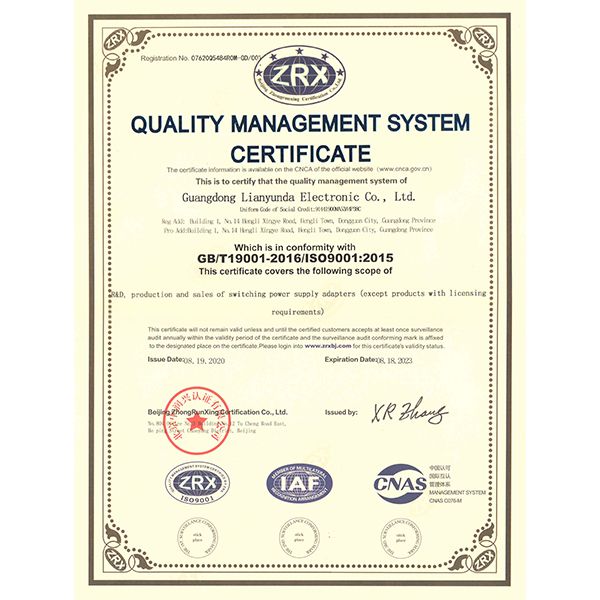

LYD Passed 105 countries national safety certification such as UL, CUL, TUV-GS, CCC, CB, UKCA, PSE, KC, KCC, SAA, FCC, CE, AR, RoHS, DOE VI, etc. LYD power adapter passed many kinds of safety certification standards such as UL1310 class 2, medical power supply UL60601-1 / IEC60601-1, IT standard 62368 / 60950, home appliance standard 60335, power transformer 61558, LED lighting standard 61347 and so on to fulfill all needs of customers in various industries, also EMC,EMI, FCC are included.

LYD has strong R&D team, and our chief engineer has 21 years R&D experience in power supply.

LYD Garden type industrial park which is covering 12000m2, integrating Office Building, Production Building, Dormitory Building. LYD provides a perfect environment for employees.

LYD built up intelligent Industry 4.0 workshop with fully automatic production lines including SMT Machine, AI Machine, Wave Soldering Machines, Automatic Injection Machines, Automatic Assembling Machine, Automatic Ultrasonic Wave Machine, Automatic Testing Equipment, etc.

QUALITY CONTROL